Innovative Uses of Laser Tools in Mining and Tunneling

Image Credit: Freepik

Image Credit: Freepik

Laser tools have greatly improved mining and tunneling operations. They offer better accuracy, efficiency, and safety. From mapping to aligning equipment, laser tools are now essential in modern mining. Let's look at some of the most useful ways lasers are used in mining and tunneling.

Laser Scanning for Mine Mapping

3D laser scanning is a big step forward in mine mapping. It quickly and accurately maps underground spaces, showing the mine's shape, rock types, and possible dangers. Benefits include:

- Very accurate measurements, down to millimeters

- Fast data collection, saving time and improving safety

- Detailed 3D models for better planning

- Ability to see changes in the mine's shape over time

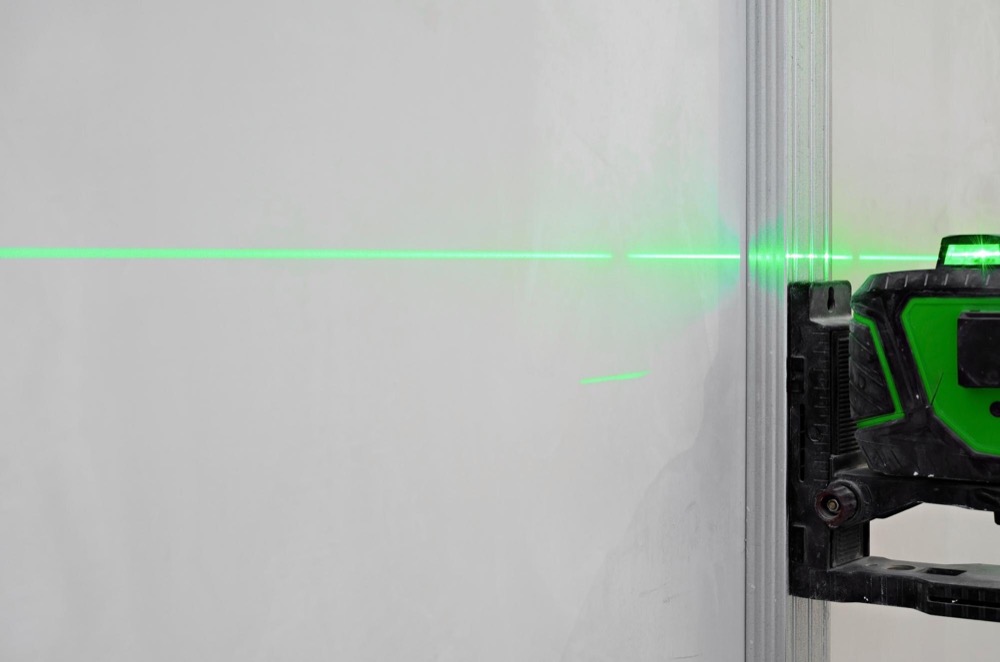

Tunnel Boring Machine Guidance

Lasers help guide tunnel boring machines (TBMs) more accurately. By shining a laser line along the planned tunnel path, operators can keep the TBM on track. This leads to straighter tunnels, less wasted rock, and faster project completion.

Equipment Alignment

Properly aligned mining equipment works better and lasts longer. Laser alignment tools offer several benefits:

- More accurate alignment, reducing equipment wear

- Faster alignment, reducing downtime

- Easy to use, needing less training

- Works for many types of equipment, from conveyor belts to crushers

Rock Bolt Installation

Lasers have made installing rock bolts faster and more accurate. These systems project a laser pattern on the rock face, showing exactly where to place bolts. This ensures bolts are spaced and angled correctly, making underground areas more stable.

Collision Avoidance in Underground Mining

Laser sensors are now used to prevent collisions between vehicles and people in underground mines. These systems detect obstacles and warn operators, reducing accident risks in dark environments.

Ore Grade Control

A new technology called laser-induced breakdown spectroscopy (LIBS) analyzes ore quality in real-time. It uses a laser to create a small spark from a rock sample, then analyzes the light to determine what elements are in the rock. Benefits include:

- Quick analysis for on-the-spot decisions

- Little sample preparation needed

- Can detect many elements at once

- Can be used with automated mining systems

At Mine Safe Electronics Inc., we know how important laser technology is for mining and tunneling. Our laser tools are made to meet the industry's needs, improving safety, efficiency, and accuracy.

To learn more about how our laser tools can improve your mining or tunneling work, contact us at 1-800-523-1579 or check out our products.

‹ Back